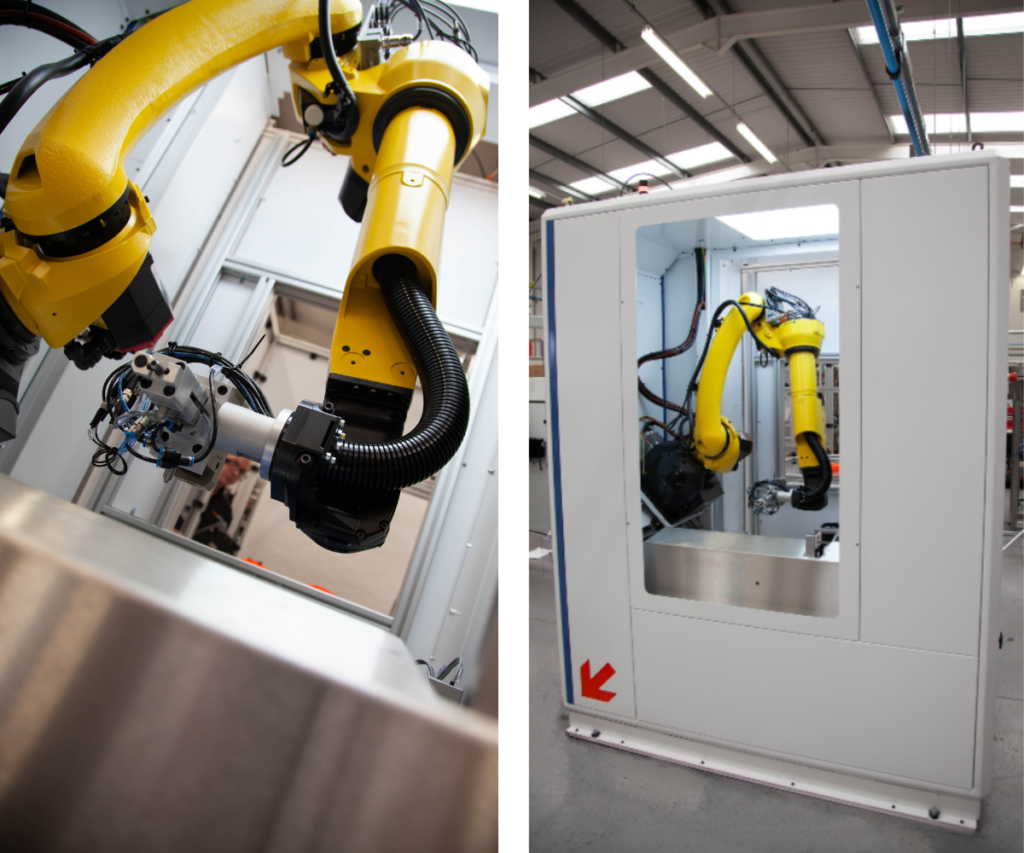

Is your company looking for a robotic process tending solution? If so we can help. Tendapod, the unique solution from Mechtech Automation Group has been specifically designed for robotic process tending automation. Tendapod has three solution levels available, but today we feature the flagship solution, the Tendapod XL.

Designed specifically for high technology sectors such as Medical Device, Orthopaedic, Aerospace and Electrification, Tendapod XL’s intelligent control and feature rich HMI enables connectivity to your MES or ERP systems for component tracking and traceability, product or batch confirmation, monitoring and prioritisation, user login access and remote access via a mobile device or desktop pc.

Not only can Tendapod XL tend a primary system such as a CNC (Computer Numerical Control) or CMM (Coordinate Measurement Machines), it can also tend secondary applications for product cleaning, polishing and buffing, gauges and inspection.

The key features are –

- Smallest Footprint

- AMR Ready

- Dual Tending (Machines or processes can be tending both sides of the Tendapod XL)

- Secondary Process Tending

Medical Device/ Feature Rich Ready User Interface

The Tendapod XL gives you the ability to integrate multiple automated tending machines to work together as one intelligent production line, and further optimise your factory floor space, giving you the ability to run multiple lines at once. The Feature Rich User Interface includes an intelligent tote lift and management system enabling the system to be either manually loaded and unloaded or automatically with the use of AMRs, whilst the tending system is in operation without delaying or slowing down of the process

Contact the team at Mechtech Automation Group today to find out more about Tendapod XL, the leading, innovative robotic tending solution. contact@mechtech.group

Recent Comments