Production Lines

Built to suit customer specifications

Production Lines

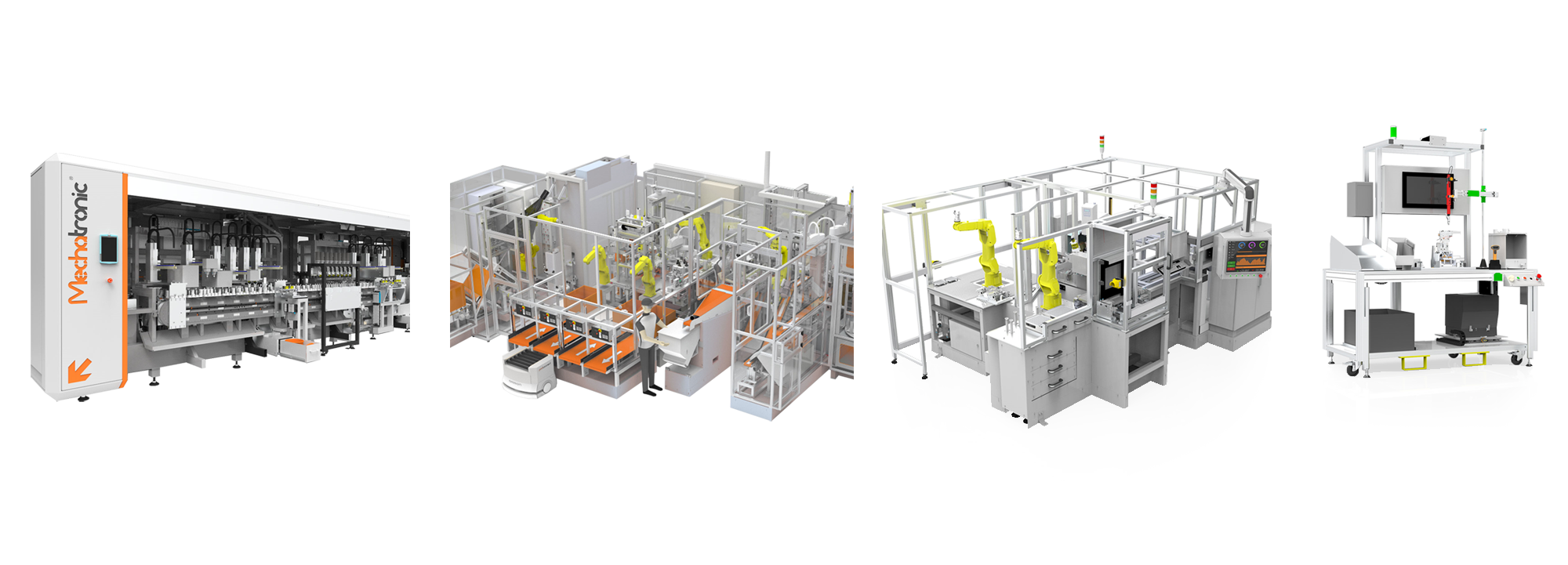

Presently, the production line landscape is dramatically changing. The fast pace of technology development has created an increased demand for higher performance lines, greater flexibility of product coupled with line layouts and machine connectivity and so our Beyond Smart solution was born.

Data collection, process monitoring and connection to in-house MES or ERP systems is becoming the norm. Mechatronic has invested significantly in our machine design and control systems to provide our customers with state-of-the-art machine functionality, giving you unrivalled connectivity, live data and machine performance at your fingertips.

Our team of expert engineers will work with you to tailor a production line to suit your exact needs and bring an idea to reality!

We work collaboratively with our customers in the following sectors:

'A production line is described as an arrangement in a factory in which a thing being manufactured is passed through a set of linear sequences of mechanical or manual operations' (definition from Oxford dictionary).

With many solutions and technologies available on the market today that could solve a production line requirement, Mechatronic’s experienced engineering team will help you choose the solution to ensure your specific industry, technical, performance and budget requirements are achieved.

Typical elements of a production line are:

- Component feeding and handling

- Transfer system

- Assembly

- Testing

- Inspection

- Labelling/Laser Marking

- Packing & Palletising

Our in-house team of experienced engineers has over 33 years of automation production equipment know-how. Contact a member of our team today to see how we can assist you further.

How we work

Initial site visit

Identify any risks in the project

Detailed

quotation

Prove the

concept

Mechatronic is a champion of digitized manufacturing and we can help you on your transformation journey, leading to increased levels of production, higher component quality, greater profitability, and an elevated level of control of your production.

Let us work collaboratively with you to understand the strategy, production drivers, performance requirements and potential risks of the line. No one knows your product better than you; it is our task to extract this information to:

- Develop process and technology mapping

- Risk assessments and PoP (Proof of Principle) studies

- Construct line concept layouts in 2D and 3D formats

- Offer 3D simulations to offer greater visibility of the solution

- Work collaboratively to understand and meet budget demands

- Understand future service and maintenance support requirements

Production lines come in many different formats, below is a general overview of technologies that Mechatronic can offer:

pallet transport

system

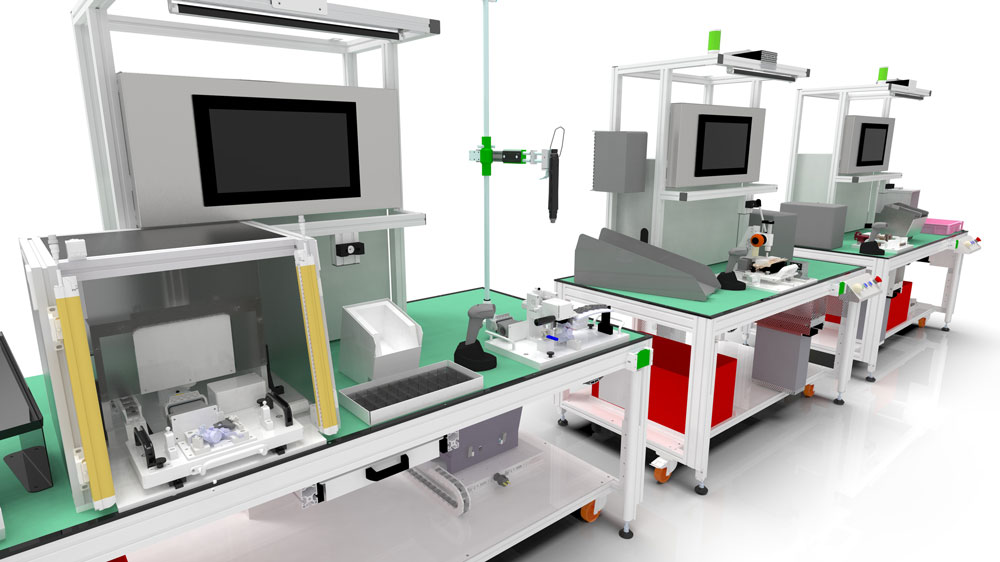

Manual line

This type of line is flexible. They are ideal for larger bulkier type products. They can be integrated with manually loaded, automated stations if an assembly tasked requires a high level of accuracy and repeatability, if it is dangerous or if it is a strain on the associate to assemble. Generally, 10-30 second cycle times are achieved depending on the process and product.

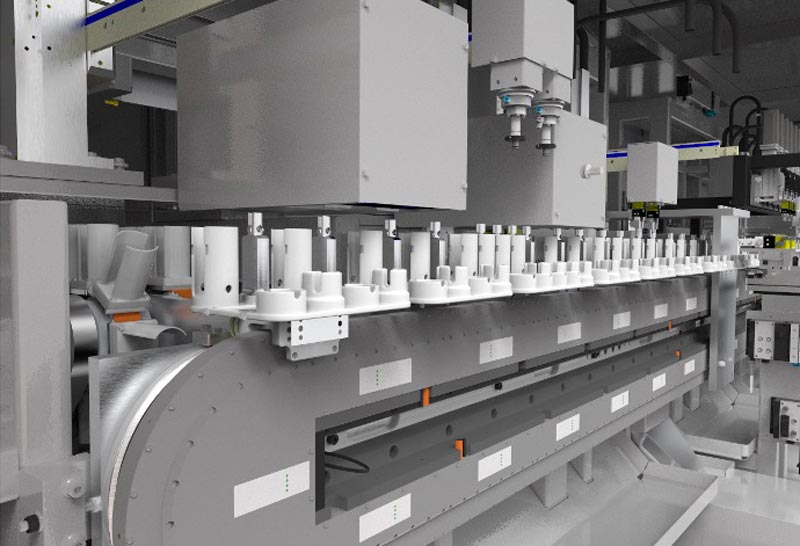

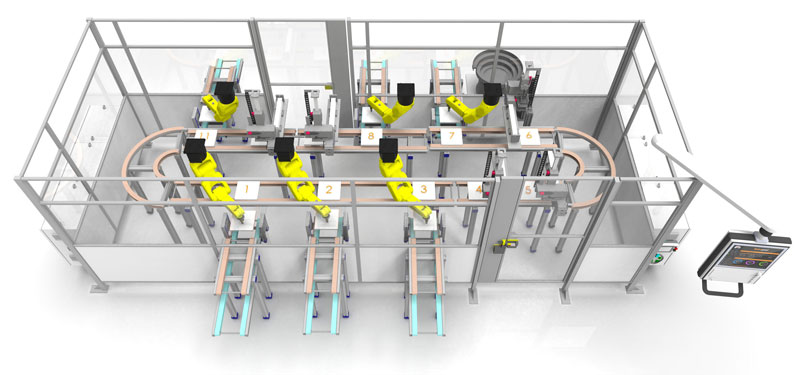

Pallet Transfer

Pallet transfer systems can be fully automated or a combination of manual and automated stations. They are used in a broad range of industries and more suited when the output requirement of the line is higher, the product variation is mixed and generally small to medium in size. In most cases, the product has been designed with automation in mind and so assembly from above, below or to the side of the component is common. For more complex assemblies, a manual station maybe introduced.

Generally, 5-10 second cycle times are achieved depending on the process and product, this takes in to account indexing time of 1 -2 seconds to transfer the pallet from one station to another.

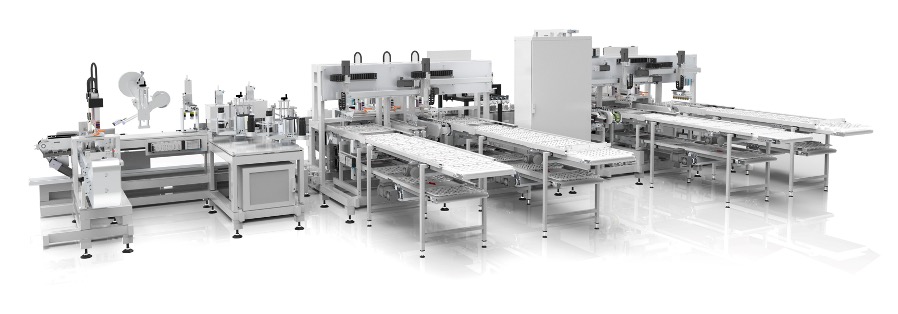

Indexing conveyor/ Programmable pallet system

Generally used where product variation is limited, accurate and repeatable assembly is required, and a high output is needed (typically 1.5-3 second cycle times are achievable). They are normally fully automated and handle products that have been designed with automation in mind. Component infeed systems can be from bulk using bowl feed systems or, in certain sectors like MedTech, components can be tray fed to the line in stacks to offer greater autonomy. It is key to note that with higher output, you need suitable feed systems that offer greater autonomy to reduce the time needed by an associate to tend the line.

This is also relevant in machine testing during build. There is a cost associated to providing samples for build. To ensure the machine is adequately tested at full run up rate prior to FAT, in some cases this cost can be significant depending on the price and volume of component required.

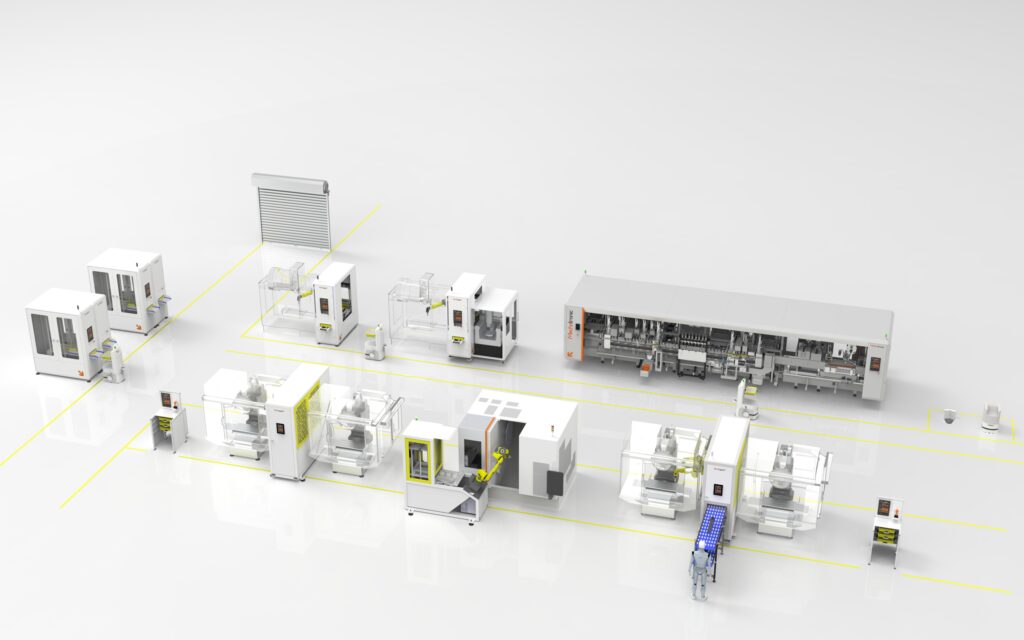

Flexible Manufacturing

More and more there is a growing demand for flexible manufacturing systems. With the advancement of AMR (Autonomous Mobile Robots) technology, no longer do you have to abide by a strict linear production line. It is possible to have satellite automated assembly or process stations and link them together using AMR technology and still have full component track and traceability.

A flexible production line can combine bespoke automation, standard robotic solutions from our Robopod range with existing automated production assets. To view our Beyond Smart solution Get in touch for more details.

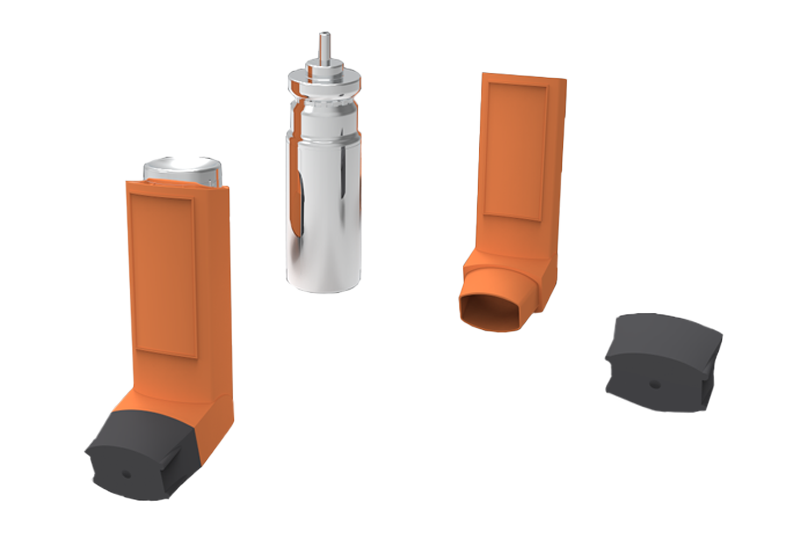

Sector: Medical Device

Component: Auto Injection Device

Cycle time: 40 components/minute (1.5 seconds part to part)

Technology: Mechatronic’s Assembly Platform (MAP) – Integrated with programmable pallet transfer systems for high speed and accuracy

Processes:

- Component Tray infeed systems

- Component orientation

- Vision Checks

- Assembly

- Test

- Label

Sector: Automotive

Component – HUD – Head Up Display

Cycle time – 2 component/minute (30seconds part to part)

Technology: Combination of 12 manual assembly benches and 7 automated stations

Processes:

- 12 off Bench assembly station with manual screwdrivers part storage and fixtures

- 5 off twin load automated screwdriver stations

- 1 off twin load robotic gluing station

- 1 off pallet load, Robotic end of line test stations

- Fully connected control

Benefits of Production Lines

Tailored to suit your product

Increase productivity and product quality

Achieve higher output and greater profitability

What We Do

Consult

We take the time working collaboratively with you to fully understand your needs and ensure a successful project outcome.

Design

We work collaboratively with you to identify your key project deliverables and develop the concept utilising the latest design, modeling and 3D simulation software.

Build

A dedicated project manager will work with you throughout the life of the project and ensure project progress is communicated effectively and key milestones are achieved.

Install

Following factory acceptance, our team provides you with a comprehensive onsite installation, commissioning, and qualification service.

Service