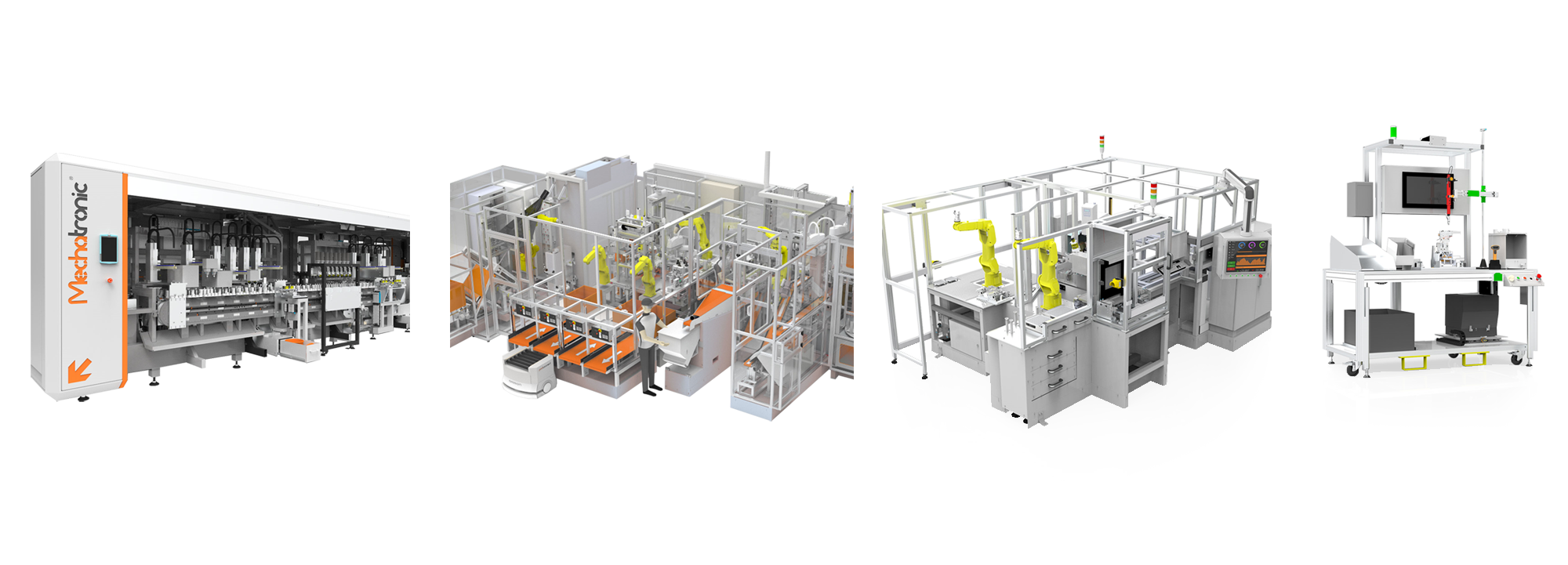

Bespoke Automation Solutions

Specially Tailored to revolutionise production

Bespoke Automation Solutions

Mechatronic is one of the UK’s leading providers of innovative Beyond Smart automation solutions and system integration services.

Established in 1988 and based in Birmingham, Mechatronic has an exceptional reputation for designing, manufacturing and delivering some of the most ingenious bespoke automated manufacturing, processing and packing solutions for all industries including:

Specially tailored to you

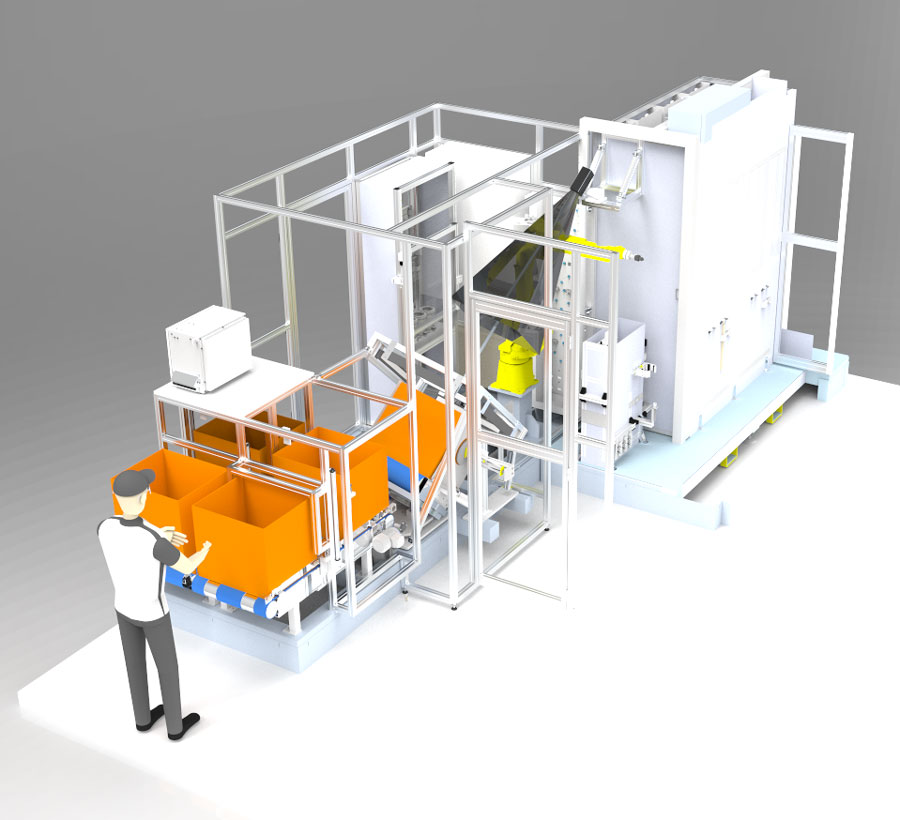

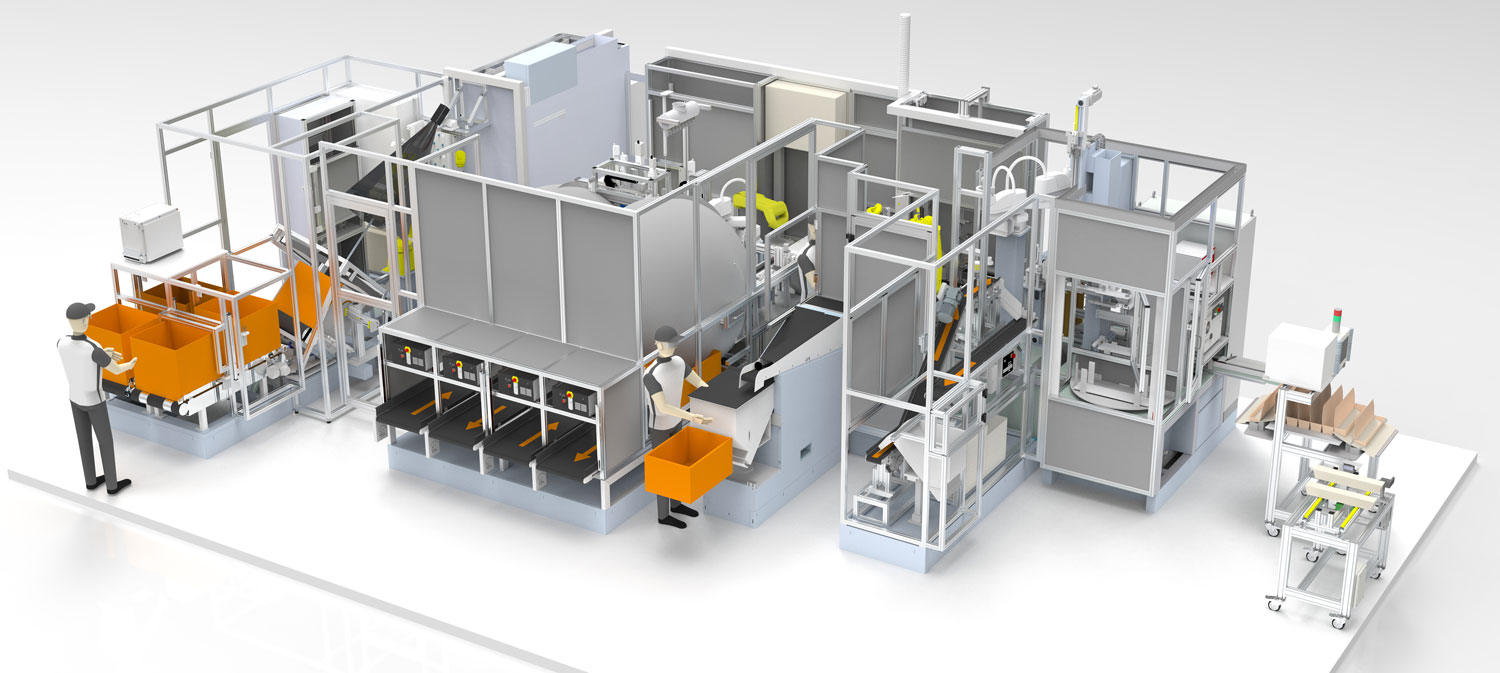

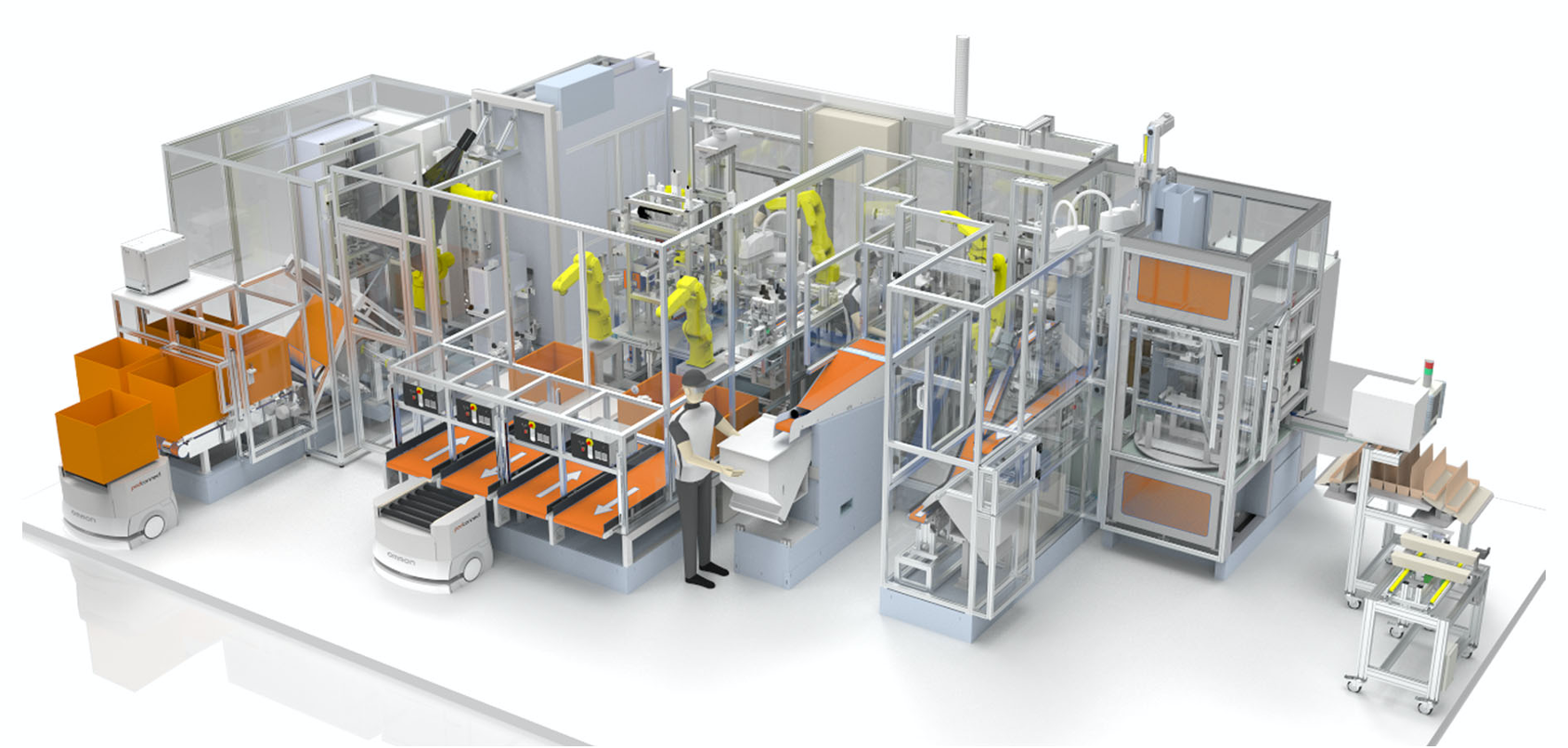

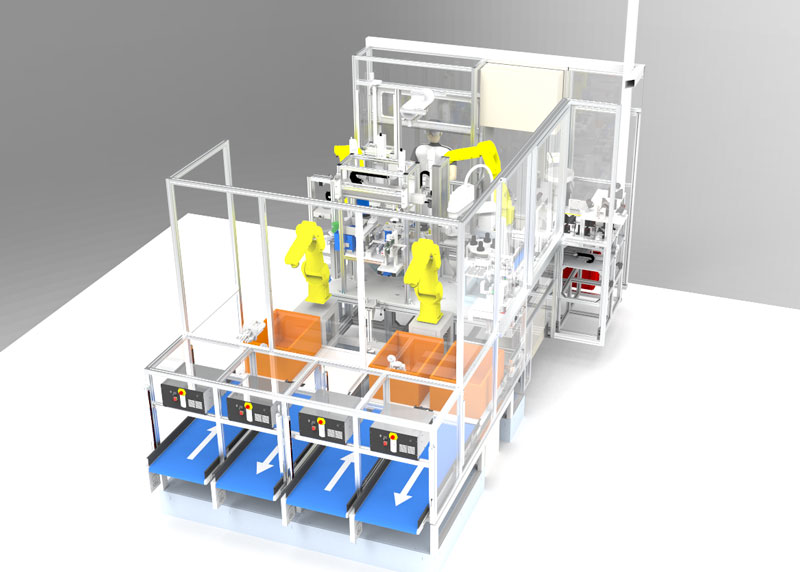

Bespoke automation is a solution that is conceived from a customer’s idea, specific need or requirement and then transformed into reality through collaborative working and concept development between Mechatronics’ sales team and the customer’s projects team.

It could be as simple as automating a single process, a semi-automated assembly bench, through to a multi-component assembly machine or automate multiple processes in one cell.

Whatever the requirement, Mechatronic has the experience, skill set, and thought leading innovative thinking to produce a solution that will:

- Exceed expectations

- Increase production output

- Increase product quality

- Guaranteed production support from MAGserv

Benefits of Bespoke Solutions

More uniform products

Reduced production

cost by increasing

efficiency

Improved

organisation for

regular and timely delivery

Fully automate your production line

with the help from podconnect

(Autonomous mobile robot)

The Mechatronic team looks to understand our customer’s processes and specifications fully, in order to offer the best solution that not only meets, but exceeds the customer’s requirements.

From an initial site visit, we aim to identify any risks in the project through a detailed quotation approach. Once the risks have been identified, a course of action might be to undertake a ‘Proof of Principle’ (PoP) study in the form of trials or manufacturing development tools to prove the concept and mitigate those risks to ensure a successful outcome. Our team offers project and risk management and outstanding customer support which has steered Mechatronic to a 85% repeat business score from our customers, making us the automation solutions provider you can trust.

Projects & Technologies

The types of bespoke projects and technologies Mechatronic has been involved with are:

Laser Automation:

Marking, Welding

Rotary, Linear & CAM Indexing Systems:

Semi/Fully Automated, Assembly, High Speed Assembly, Leak Testing

Marking, Riveting/Insertion, Pressing/Crimping, Vision Inspection

Pallet Transfer Systems:

Semi/Fully Automated, Multiple Component Assembly, Leak Testing

Marking, Riveting/Insertion, Pressing/Crimping, Vision Inspection

Robotic Systems:

Spot Welding, Laser Welding, MIG Welding, Palletising, Assembly

High Speed Pick & Place, Riveting, Orientating Using Integrated Vision

Leak Test Systems, Lean Manufacturing Assembly/Processing, Marking

Riveting/Pressing, Forming, Inspection, Workstations

Production Lines:

Automotive radiators, Photocopier ink cartridges filling

Medical device sorting and assembly

Full turnkey solutions

AMRs (Autonomous Mobile Robots)

Stores To Shop Floor Component logistics

Process Tending & Component Traceability

A to B Component Process Transfer

What We Do

Consult

We take the time working collaboratively with you to fully understand your needs and ensure a successful project outcome.

Design

We work collaboratively with you to identify your key project deliverables and develop the concept utilising the latest design, modeling and 3D simulation software.

Build

A dedicated project manager will work with you throughout the life of the project and ensure project progress is communicated effectively and key milestones are achieved.

Install

Following factory acceptance, our team provides you with a comprehensive onsite installation, commissioning, and qualification service.

Service