Through IoT technology, machines can seamlessly communicate to each other and in some cases react to problems that arise. The enhancement in precision manufacturing by these smart technological systems enables the opportunity to lower error rates and product failures thus reducing huge costs historically faced by manufacturers and significantly increasing productivity.

By adopting smart factory thinking, production will become more seamless, robust and visual, from planning all the way to actual operations.

One downside to smart manufacturing can be the upfront cost of implementation. But, converting your entire manufacturing process into a Smart Factory all at once is not compulsory. A Smart Factory transformation can happen step by step, to best match the demands, scope, and growth of your business. This is where Mechtech Automation Group can step in and help you achieve your transformation journey.

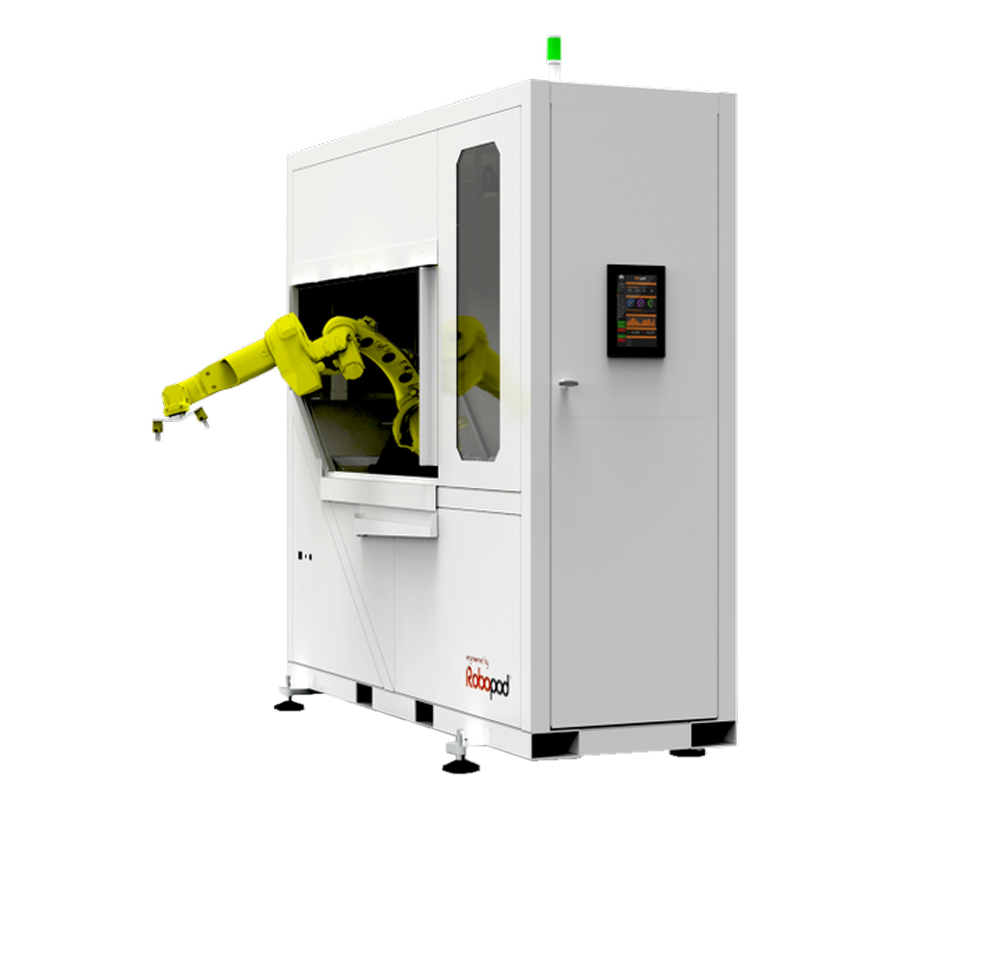

Mechtech Automation Group, incorporating Robopod, Mechatronic and MAGserv have thought leading thinking coupled with the ability to offer tailored and standard automated solutions for smart digital manufacturing. Robopod’s flexible manufacturing systems enables you to have the building blocks of smart factories, you no longer need to only offer linear production lines. Robopod presents the opportunity to position multiple Pod’s around the factory floor in locations which best suit your production requirements, performing different tasks. Robopod is an innovative plug-and-play reconfigurable robotics system, featuring a unique standardised platform, offering endlessly adaptable solutions. They can be configured with a multitude of technologies from laser marking, assembly and inspection systems to name but a few. Furthermore, Robopod stations can open the process technology within the pod to multiple component variants rather than just the variants running down a single linear assembly line.

With each Pod having the ability to communication to each other through OPC UA – machine to machine protocol for industrial automation, it is possible to link multiple Pods together to act as one flexible production line with full track and traceability of your product assembly, giving your manufacturing business unrivalled performance and rapid payback.

Component logistics from Pod to Pod can be further enhanced with the introduction of Pod Connect – Robopod’s intelligent automated solution for component and product logistics with the use of AMR’s -Autonomous Mobile Robot technology. PodConnect, guarantee’s delivery of your components or products from station to station, from warehouse to the shop floor or to a facility department without being handled by human hands reducing the risk of production contamination or mix up.

What’s more, Robopod machines can be added one at a time, as your business grows, and production demands increase.

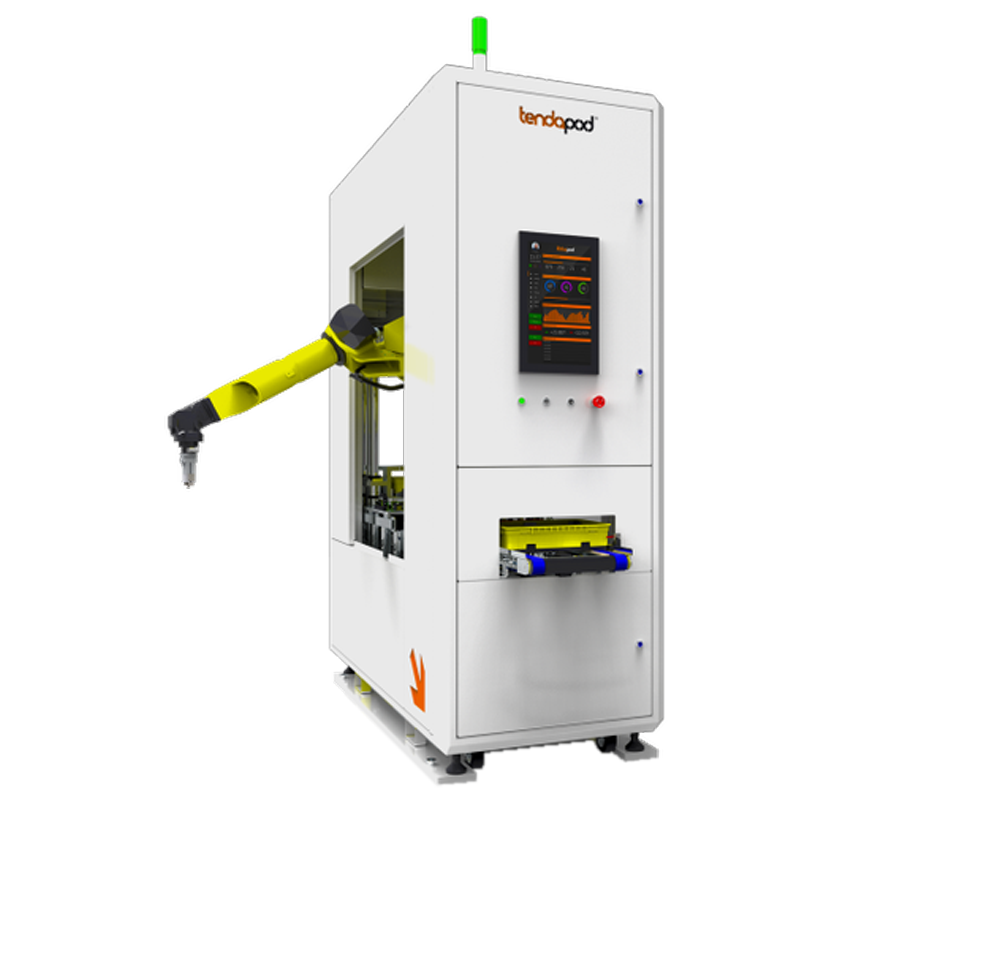

If your business requires process robotic tending automation, then the next step would be the inclusion of a smart Tendapod system. It can tend an array of CNC machine tools (front and side loading), CMM (Coordinate measurement machines), laser marking stations to name a few.

The key features of Tendapod are:

- Plug and play robotics

- Minimum footprint – (from 720mm x 1200mm – 850mm x 2000mm)

- Single or Dual tending – (ability to tend two machines (one on each side) with one robot or a single machine and additional secondary processes on the other side)

- Easily Portable

- Internal intelligent WIP (work in progress) store

- Smart Factory Control with Remote access, OEE reporting, batch management and connectivity to your MES or ERP systems.

Tendapod has three solution levels available:

Tendapod – The smallest offering at 720mm x 1200mmm footprint. This system can be configured with Robopod’s intelligent control or a base level functional control. It has four manually loaded draws, a 900mm reach 6 axis robot and is best suited for tending of CMM’s or smaller front loaded 5 axis CNC machines.

Tendapod ST – offering a footprint of 850mm x 2000mm, it has a 1.4M – 1.6M reach robot allowing for side loading of CNC machine tools and an internally WIP store of up to 9 600mm x 400mm totes. It can be configured with Robopod’s intelligent control, or a base level functional control and it is dual tending, typically used sandwiched between a CNC machine tool and a CMM or secondary process. It allows for manual loading of billet material only and is ideally used in small or large machine shops for batch machining of components.

Tendapod ST – offering a footprint of 850mm x 2000mm, it has a 1.4M – 1.6M reach robot allowing for side loading of CNC machine tools and an internally WIP store of up to 9 600mm x 400mm totes. It can be configured with Robopod’s intelligent control, or a base level functional control and it is dual tending, typically used sandwiched between a CNC machine tool and a CMM or secondary process. It allows for manual loading of billet material only and is ideally used in small or large machine shops for batch machining of components.

Alternatively, Tendapod XL – is the true smart factory machine tending solution. It gives you the ability to integrate multiple automated tending machines to work together as one intelligent production line, and further optimise your factory floor space, giving you the ability to run multiple lines at once. It has the same footprint, robot and WIP store as the Tendapod ST, but includes and intelligent tote lift and management system enabling the system to be either manually loaded and unloaded or automatically with the use of AMR’s whilst the tending system is in operation without delaying or slowing down of the process. It only comes with Robopod intelligent control offering full connectivity to your MES or ERP systems coupled with full remote access via a mobile device or desktop pc.

Alternatively, Tendapod XL – is the true smart factory machine tending solution. It gives you the ability to integrate multiple automated tending machines to work together as one intelligent production line, and further optimise your factory floor space, giving you the ability to run multiple lines at once. It has the same footprint, robot and WIP store as the Tendapod ST, but includes and intelligent tote lift and management system enabling the system to be either manually loaded and unloaded or automatically with the use of AMR’s whilst the tending system is in operation without delaying or slowing down of the process. It only comes with Robopod intelligent control offering full connectivity to your MES or ERP systems coupled with full remote access via a mobile device or desktop pc. Finally, the Tendapod Store system provides a scalable Automated Storage Solution for your business. Also built with Tendapod’s unique compact footprint helping maximise the effectiveness of your factory floorspace, the Store can automatically manage your work in progress. A Tendapod Store can be loaded by hand, or using a Podconnect AMR, and has been specifically designed to vertically store up to 40 standard 300mm x 400mm or 600mm x 400mm euro totes. Additional storage can be added one at a time to grow as your business grows with each Tendapod Store connected through OPC UA for connected inventory management

Finally, the Tendapod Store system provides a scalable Automated Storage Solution for your business. Also built with Tendapod’s unique compact footprint helping maximise the effectiveness of your factory floorspace, the Store can automatically manage your work in progress. A Tendapod Store can be loaded by hand, or using a Podconnect AMR, and has been specifically designed to vertically store up to 40 standard 300mm x 400mm or 600mm x 400mm euro totes. Additional storage can be added one at a time to grow as your business grows with each Tendapod Store connected through OPC UA for connected inventory management

If your business is ready for a Smart Factory transformation, but requires a bespoke solution, Mechatronic can help. With over 30 years’ experience, Mechatronic is one of the UK’s leading providers of bespoke automated solutions and system integration services to a range of industry sectors. Mechatronic’s strength is the combination of innovative technology, coupled with the vast experience of the team. Bespoke automation is a solution that is conceived from a customer’s idea, specific need, or requirement, and then transformed into reality through collaborative working and concept development between Mechatronic’s sales team and the customer’s projects team. Mechatronic’s experience in providing Beyond Smart solutions will increase levels of production, increase component quality, increase profitability, and increase control over your production. Contact Mechtech Automation Group today to begin your Beyond Smart transformation.

Recent Comments